PRODUCTS

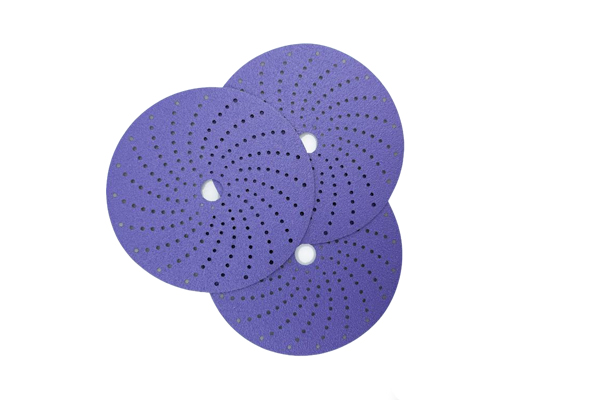

Ceramic Velcro Sanding Discs

- Product ID:

- Size: 4‘’-9‘’

- Material Science: ceramic abrasives

- INQUIRY

Utilizes microcrystalline ceramic abrasives, with a lifespan 3-5 times longer than traditional aluminum oxide sanding discs, reducing the frequency of replacements. The abrasives continuously generate new cutting edges upon fracturing, maintaining high-efficiency cutting (40% more efficient than standard sanding discs).

Suitable for high-speed angle grinders (10,000 RPM+), enhancing metal deburring and weld grinding efficiency by 35%-50%. The ceramic abrasives offer excellent heat dissipation, reducing the risk of workpiece burns, making them ideal for sensitive materials like stainless steel and titanium alloys.

Features a hook-and-loop backing for quick change design, compatible with leading angle grinder brands), saving downtime. Supports standard interfaces such as 5/8″-11 and M14, with custom non-standard bore sizes available.

Electrostatic sand planting process reduces dust generation, complying with OSHA and EU occupational health standards. Certified by REACH and RoHS, meeting European and American environmental regulations.

Applicable in metal processing, composite material, and hardwood polishing in woodworking.

Chinese products are priced at about 50%-70% of similar European and American products, with ceramic sanding discs achieving 80%-90% of the lifespan of their Western counterparts but at over 30% lower cost.

Chinese manufacturers possess proprietary ceramic abrasive formulations and sand planting technologies, whereas Southeast Asian products often rely on imported abrasives. Chinese products have a qualification rate of >97% (generally <90% in Southeast Asia), reducing the risk of customer returns.

News

Contact Us

Contact: JinKaiyan Abrasives

Phone: +86 13663827325

Tel: +86 13663827325

E-mail: cici8686@foxmail.com

Add: Weidu Industrial zone Xuchang City, Henan province in China