Velcro sanding disc product introduction

Velcro sanding disc product introduction

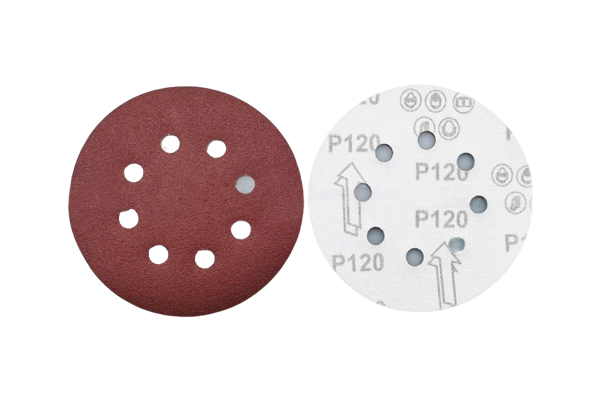

Velcro sanding disc, a widely used abrasive tool, is characterized by its Velcrobacked design that enables quick and easy attachment to and removal from compatible sanders (such as orbital sanders and random orbital sanders). It integrates highperformance abrasive materials with a convenient fastening system, making it an essential tool in fields like woodworking, metalworking, automotive repair, furniture finishing, and DIY projects. It efficiently realizes surface sanding, polishing, deburring, and rust removal.

Key Features

1. Effortless Fastening with Velcro Backing: The disc adopts a highstrength Velcro backing. During use, it can be firmly attached to the sander’s pad in just a few seconds, and removed quickly when replacing with a new disc or switching grits—no tools are required, which significantly saves operation time and improves work efficiency.

2. Diverse Abrasive Material Options: To meet different sanding needs, the disc is available with various abrasive materials:

Aluminum Oxide: The most commonly used material, featuring good durability and costeffectiveness. It is suitable for sanding wood, plastic, and soft metals (e.g., aluminum).

Silicon Carbide: It has excellent hardness and heat resistance, making it ideal for sanding hard metals (e.g., stainless steel), glass, ceramics, and stone.

Zirconia Alumina: With high toughness and wear resistance, it is mainly used for heavyduty sanding tasks, such as grinding weld seams of metals and sanding hard wood.

3. Wide Grit Range for Versatile Applications: It covers a comprehensive grit range from coarse to fine, allowing users to choose according to specific surface treatment requirements:

Coarse Grit (40 80): Suitable for initial sanding, such as removing deep scratches, leveling uneven surfaces, and stripping old paints or coatings.

Medium Grit (100 180): Used for intermediate sanding, which can smooth the surface after coarse sanding and prepare for fine sanding.

Fine Grit (220 400): Applied for fine sanding to create a smooth surface, laying a good foundation for painting, varnishing, or polishing.

ExtraFine Grit (500 1000): Mainly used for precision polishing, such as finishing the surface of highend furniture, automotive parts, and electronic products to achieve a smooth and glossy effect.

4. Stable Performance and Long Service Life: The abrasive grains on the disc are evenly bonded using advanced adhesive technology, which effectively prevents grain shedding during highspeed sanding. Additionally, some highend models are designed with a dustextraction hole structure—when used with a sander equipped with a dust collection system, it can timely remove sanding dust, reduce clogging of the disc’s abrasive surface, and further extend the disc’s service life while keeping the working environment clean.

News

Contact Us

Contact: JinKaiyan Abrasives

Phone: +86 13663827325

Tel: +86 13663827325

E-mail: cici8686@foxmail.com

Add: Weidu Industrial zone Xuchang City, Henan province in China